Enroll to get our most up-to-date posts! From strategy to completed products, sheet metal bending demands a deliberate, believed-out layout and intentional production. There are several key steps to successful bending:

And unlike asphalt, slate, or clay roofs that keep onto solar heat once the Sunshine goes down, metal immediately releases its heat back again in the ambiance.

When bending a sheet, the fabric must be bent past its needed angle. It is because sheet metal possesses a substantial-bending skill that permits it to spring back again to its original situation.

Each metal and asphalt shingle roofs is usually wonderful choices for your own home. The main variations lie in the associated fee and restore.

Sheet metal usually refers back to the use of fabric beneath 3mm thick, but laser reducing and bending can be used on elements in extra of this effortlessly. The flexibleness of the process about choice of elements, thicknesses and complexity in the components it may possibly make makes it perfect for producing a big range of areas, used in just about every market from automotive, transport, domestic appliances, home furnishings, industrial products and more.

The most important downside to Moderate Steel may be the requirement for coating, as rust will kind within the existence of humidity. Galvanised steel is obtainable to counter this problem, furnishing a hard putting on pre-applied zinc coating to avoid rust.

If a major-responsibility hailstorm—or foot traffic—puts dents your metal roof, it may appear terrible, even so the roofing by itself isn’t compromised.

The rationale for this spacing is that holes and slots will turn into deformed should they are located way too near a bend. In addition, holes and slots really should be spaced at least 2 instances the fabric thickness from the sting of your component if you'd like to prevent bulging.

(A push brake is an easy device utilized in sheet metal bending processes, it types preferred bends around the sheet by working to clamp the sheet metal in position for push involving the punch plus the die)

To easily transform gauges into inches or millimeters, consider our sheet metal gauge chart. Find out more with regard to the differences concerning metal sheet and plate.

Drinking website water jet cutters are specially handy for reducing sheet metals that has a reduced melting place because they do not make heat which could unduly deform the metal.

You will likely hear sound from a metal roof throughout a storm. Despite the fact that some people discover the seem of rain hitting a metal roof calming, this is one area to think about, particularly if you’re delicate to sure noises.

There are several metal roofing solutions. Here are the commonest styles you’ll obtain for household housing.

When the blank is developed, the following stage would be to form sheet metal using many applications, but most often some kind of brake. A brake press may be handbook or automatic and makes use of die inserts to create a wished-for angular bend, forming The 2-dimensional sheet into a three-dimensional item.

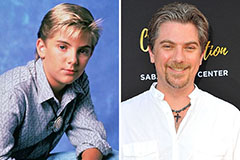

Haley Joel Osment Then & Now!

Haley Joel Osment Then & Now! Jenna Von Oy Then & Now!

Jenna Von Oy Then & Now! Jeremy Miller Then & Now!

Jeremy Miller Then & Now! Soleil Moon Frye Then & Now!

Soleil Moon Frye Then & Now! Megyn Kelly Then & Now!

Megyn Kelly Then & Now!