A different advantage I’ve found is always that sheet metal offers exceptional conductive properties, rendering it efficient for electrical and thermal apps. It’s also highly proof against corrosion, making sure durability and prolonged-time period dependability.

The material is then immersed within a molten zinc tub in a temperature of all-around 460°C to produce a zinc-coated materials. SGCC is tougher than SECC but has lousy ductility, a thicker zinc layer, and weak weldability.

Of course! Metal roofs are Power economical within their generation and performance. Partly made from recycled elements and entirely recyclable them selves, metal roof parts Possess a smaller carbon footprint than other options.

Architectural asphalt shingles: Architectural shingles are made of comparable asphalt substance, Nevertheless they’re thicker and sturdier. They’re costlier than standard asphalt shingles, but they've got a life expectancy of about thirty decades and will arise to far more serious weather conditions.

This table depicts the final tolerances for Xometry’s sheet metal solutions. Learn more about our sheet metal production benchmarks.

Metal roofs Price tag greater than asphalt shingles, but they also previous a lot longer and have a tendency to provide much more Strength effectiveness.

As the applying of sheet metal continues to increase, the look of sheet metal sections has become a vital element of item growth.

The back again gauge is usually a working component that controls the location from the bending line, although the upper and reduce molds are utilised to regulate the bending angle and internal radius in the workpiece. If the workpiece is competent or not is mainly determined by these three sections.

The symmetry can't be assured in each and every instance, but then Ensure that it is well recognized how the production needs to be completed.

These roofs are put in with uncovered fasteners, developing a rustic look. They can be painted or left unpainted. The metal may be click here pressed into distinct variations, and ribbed, corrugated, and crimped are prevalent models. Sheet metal is definitely the least pricey sort of roofing since it is usually easy to Reduce and shape and operates concerning $75 and $600 for every roofing sq..

The Pleasure of this method is akin to unfolding a street map of endless opportunities, which results in the creation of significant-high quality, tailored precision metal parts.

Our CNC push brake operators have the metal forming and metal fabrication practical experience required to manufacture the tailor made parts you would like to your subassemblies.

Immediately after bending, always inspect the final merchandise for precision and quality. This contains checking the bend angles and measurements and in search of any defects, such as cracks or deformations.

There are several various ways to form sheet metal, but they all boil all the way down to two broad categories: sheet metal can possibly be Lower or formed.

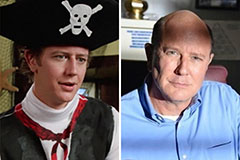

Haley Joel Osment Then & Now!

Haley Joel Osment Then & Now! Lark Voorhies Then & Now!

Lark Voorhies Then & Now! Judge Reinhold Then & Now!

Judge Reinhold Then & Now! Mason Reese Then & Now!

Mason Reese Then & Now! Lisa Whelchel Then & Now!

Lisa Whelchel Then & Now!